What we do?

What we do?

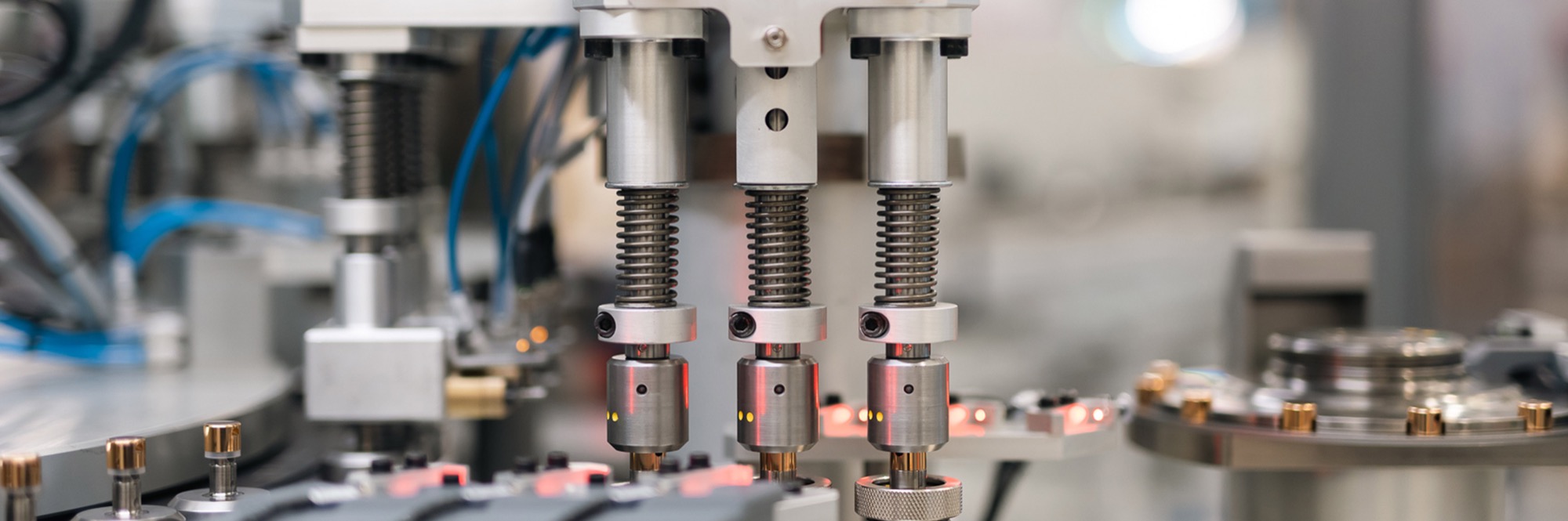

At CMTEC, we specialize in developing advanced

technological solutions in engineering and industrial

machinery manufacturing

We specialize in process automation

Design and Manufacturing of Machinery. We provide tailored, high-performance solutions to streamline and optimize your automation processes.

After sale service. Respondemos con agilidad, buscamos soluciones y ofrecemos una atención personalizada y continua en cada caso.

Technical Consultancy.

Industrial 3D Design and Printing Service.

CMTEC is advancing

technology!

We are pioneers in the application of XTS technology.

Our expertise allows us to combine XTS technology, electronics, robotics, artificial vision, among others, to obtain the best solution and results for our clients.

AT CMTEC we are

CommittedflexiblesInnovativeApproachableSolution-orientedResourceful

CommittedFlexibleInnovativeApproachableSolution-orientedResourceful