Projects

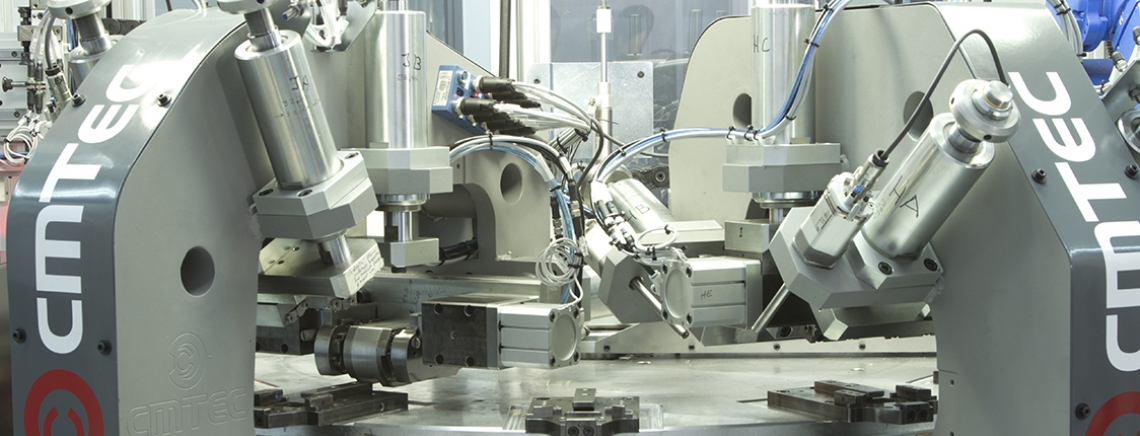

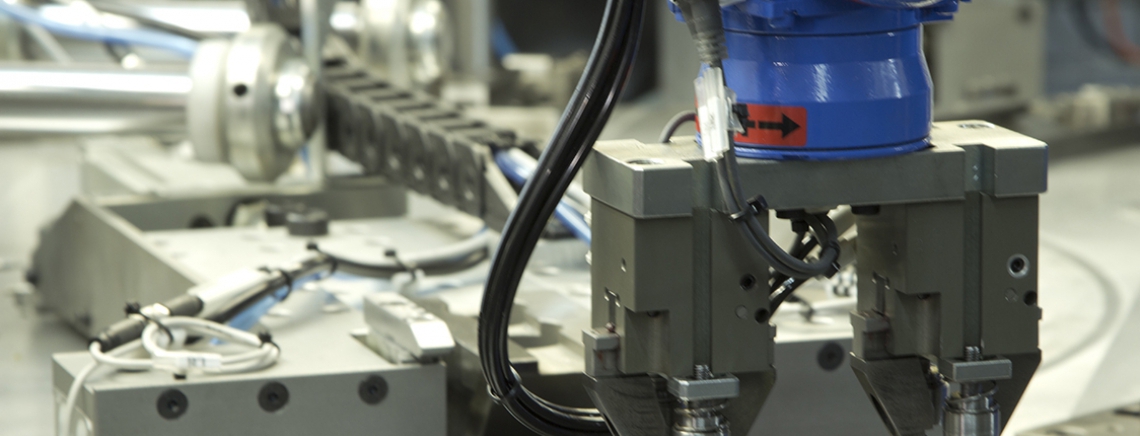

Bar assembly machine

Project description

This a machine built to mount bars in the frames, at a rate of one piece every 3 seconds.

It is an intermittent pneumatic rotary machine, which is driven by a central electric reducer motor and various pneumatic and hydraulic cylinders. Robotics and artificial vision technologies are also used in this project.

This machine has seven work stations capable of processing up to five different models. The machine consists of a frame feeding station with a scara robot arm, a welding module, a screw control, a female control, a bar feeder with a 6-axis robot, a bar clinch, an inspection module for artificial vision and selective extraction.

Details

- Year: 2015

- Technology used: robotic, pneumatic and hydraulic

- Sector: automobile

- Blows per minute: 1 piece every 3 seconds

- No. of components: 4 x (5 models)